Products:ABF filter: ABF automatic backflush filters

-

Introduction ABF automatic backflush Filters

The ABF is a fully automatic backflush filter and was developed as a simple and efficient way to remove floating pollutions from liquids.

Because of the specific properties of the filter - a high efficiency, reliability, high output, user friendliness and little required maintenance - it has found its way into different branches of industry.

Filter applications

ABF filters can be found in the chemical industry, food and drinks industry, plastics industry, agriculture and horticulture, facilities for drinking water, sewage maintence installations etc.

Much seen applications are things such as: The filtration of surface water, cooling water / cooling tower systems, influent and effluent filtration, protection of equipment (such as heat exchangers, sprinklers, membrane filters / rerverse osmosis), irrigation and the improvement of products.

For an example of the last mentioned, you could think of the filtration of sugarsap, wich is one of our specialties.

-

ABF specific advantages

1 Automatic cleaning cyce

- Fully automatic backflush proces which will start when the pressure reaches a certain point. This point can be programmed.

- Backflush with the present liquid- and processpressure.

- Little dissipation of pressure over the filter (Which will cut back on electricity costs!)

- Backflush through means of small nozzles, so that a high backflushspeed can be achieved, which will optimize the cleaning process.

-

2 Continuous flow

- Flow during the washing process

- High capacity and compact units

- Flexibele PLC besturing

3 Little required maintenance

Short pay-back period because of the favourable price, low installation and maintenance costs, while saving money on energy and maintenance costs of other equipment.

4 No consumtion of filterresources

- no consumption or discharge of filterbags-candles and/or filterresources

-

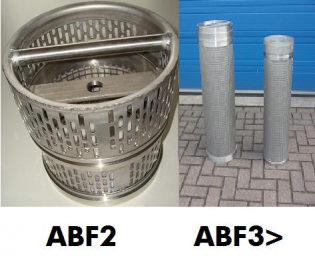

Filterelement ABF2 and ABF3

On the photo ABF2 you can see the filterelement as it is used in the smallest ABF2 filter. The filter is divided into two sections, the filter for the bigger rougher parts on the top side and the filter for the smaller parts underneath it.

On the photo ABF3 you can see the filter for the smaller parts as it is used in all ABF filtermodels 3, 4, 5, 6, 7 and 8.

The filterprecision is chosen depending on the situation, and is made through the application of the right filterscreen.

The precision is made from 10 micron to the most used filtration with 100-200-300-400-500 micron.

On the previous photo you can also see the dirtcollector, which is equipped with dirtnozzles. These drain away the collected dirt during the cleaning.

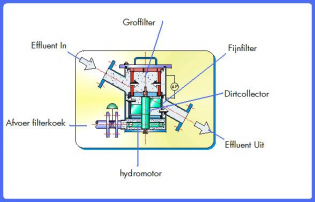

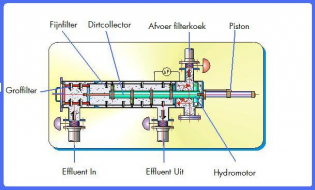

Operation of the ABF selfcleaning filter

The ABF fully automatic selfcleaning liquidfilters operate with concentrated backflush, which is initiated by measuring the difference in pressure. The liquidpressure present in the ABF is used for the backflush. Because of the way the cleaning process works, with small backflushnozzles, the filterelement is cleaned optimally, while the filtration process is not interrupted. Big filtration acuteness is achieved by using stainless steel filtration netting.

Filterfineness is also easily adaptable afterwards, to match the process-circumstances.

- The liquid flows through the filter in the indicated direction.

- The red filterscreen is the rough filter.

- The green "dirtnozzle" is a rotating dirt-De groene ‘dirtnozzle’ is een roterende waste-pipe, which cleans the filterscreen during the rotating cleaningprocedure.

- The removal of the dirty liquidflow is in the direction of the hydromotor and the waste-pipe.

ABF Models chart:

|

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Project: Nigeria sugarsap filtration

In the new cane sugar factory in Nigeria, Holland filter has provided a complete filterinstallation-skid, fitted with 13 filterhousings for the filtration of thin sap with the production of cane sugar.

Brewery cooling water filtration

At a well-known brewery, two ABF filters have been installed in the cooling water system to keep the cooling water that flows through the changers clean.

Paperfactory intake waterfiltration

For the production of paper, a lot of water is used. This water often comes from the nearest river. Here, there are two ABF filters installed to make the water suited for the process.

Tapwater filtration

To prevent the intake of undesired amounts of contaminated tapwater, there is a ABF filter installed here, which guarantuees a 100% acurate filtration at a continuous flow.

Waterhindrance, extra filtration rainwater, groundwater

When there has been a heavy rain, the surplus of location water has to be pre-filtered to spare the waste-water installation.

Intake processing water in the harbour of Rotterdam

Appliance of ABF for several waterfiltrations in the harbour, also at high temperatures, at which the filter is fitted with a jacket.

Filtration of pondwater

Across the street at the station in Venlo, a nice pond was made, at which great amounts of water are constantly being filtered.

For this function, an ABF fully automatic system was chosen to keep frequent maintenance at a minimum.

Bigger particles can be removed separately and next the smaller particles can be routed to the sewers through the ABF filtration.