Applications:Sugar filtration: Sugar filtration

Sugar Filtration

MODERN FILTRATION METHOD FOR SUGAR JUICE

Sugar industry already has a long tradition with Separation and Filtration.

Filtration is that important in only a few industries, so the engineers in the sugar mills have a very practical experience and much knowledge in this field.

Most of the filtering systems in sugar mills are designed for low capacities and pressures and usually filter-aids are used to build up a filter-cake to reach the necessary filtration-level.

Disadvantages of these filtration systeeed of a very large floor area, heavy constructions, usage and disposal of filteraids and much attention of the operators. This results in high exploitation-costs.

Holland Filter started in sugar industry with delivery of selfcleaning filter systems for beetwash water and for condensers (raw juice and carbonatation). In a later stadium the engineers of a sugar mill asked to develop a system for the filtration of sugar juice (thick juice) just before crystallization. In 1986 Holland Filter developed the first fully automatic selfcleaning filter system for a sugar mill of the largest sugar company in theNetherlands, "Suiker Unie".

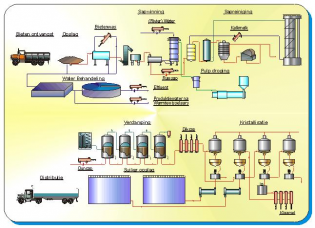

Such a system, called a "thick juice sugar installation", is a design of several ABF7 selfcleaning filters, which are connected parallel and build together.

This system is controlled by a PLC according to the latest modern standards. Because thick juice is a rather viscous and expensive product for the sugar factory, thin juice or hot water is used as back washing medium. This thin juice will be carried back to an earlier stage in the process flow.

There will be no loss of expensive thick juice during this filtration step.

WORKING PRINCIPLE

HOLLAND FILTER SUGAR JUICE FILTER INSTALLATION

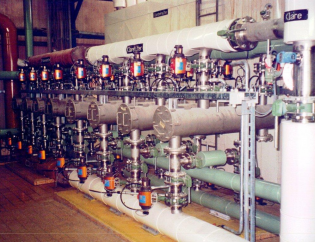

The Holland Filter Thick Juice Filter Installation consists of several ABF7 selfcleaning liquid filters, mounted parallel on a connecting pipe frame, controlled by a modern PLC control box.

Because thick juice or standard liquor is an expensive product for the sugar factory, thin juice or hot water is used as a back wash medium. This thin juice also has the advantage of a lower viscosity.

The sugar juice enters the main inlet header and flows through the filters into the main outlet header. Back washing starts at a signal of the DP-monitor, which has been set at a predetermined level.

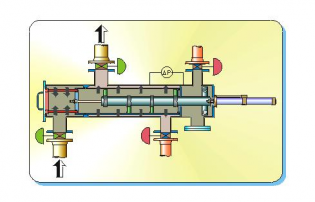

The ABF7 filter consists of 3 compartments: the coarse screen compartment, the fine screen compartment and the lower compartment. On this side of the filter also the hydraulic motor is located.