Products:Sievebend filter: Siebostatic - Siebomatic - Viebomatic

Introduction

The Holland Filter sievebend is a years old technique, which is still a good solution in watertreatment.

Sievebends are often applied in horticulture, the meatprocessing industrie and in industrial purification plants.

Sievebends are especially fit for the removal of large quantities of relatively rough pollution, with a big variaty of capacities.

The filters require minimal maintenance and are selfcleansing.

Operation sievebend filtration

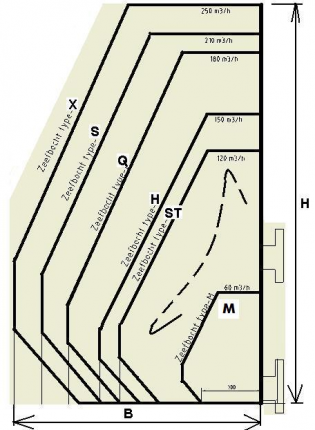

The Holland Filter sievebends are often applied for the filtration of rough particles, larger than 0,25 mm.

The static or dynamic filterscreen keeps the solid materials on the surface of the filterscreen, which causes them to be filtered from the liquid.

The liquid falls through the screen and has a selfcleansing effect.The solid materials glide off of the screen and fall into the wastecontainer standing beneath it.

Filterengineering

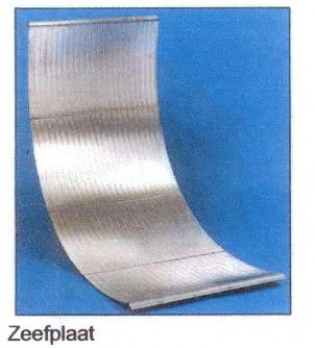

Because of the special construction of the screen, the triangular strings have been mounted a little opposed, which causes the flow of water to be divided downward.

These sharp ridges also have to be felt when you move your fingers downwards.

Sievebends are delivered made from AISI 304 stainless steel.The width of the mesh varies from 10 to 3000 micron (is decided during the order).

Voordelen zeefbocht

1 Continuous flow

During the filtering process, the liquid can flow continuously without having to interrupt the process.

2 Automatic cleaning cycle

At the downward waterflow, the filtering waste gets flushed into the container beneath it.

3 Little maintenance required

Filterscreens are made of Stainless steel 304/316-L and don't have to endure any mechanical cleaning.

4 No filteraid required

The screens filtrate without the help of filteraid.

Uitvoeringen zeefbochten

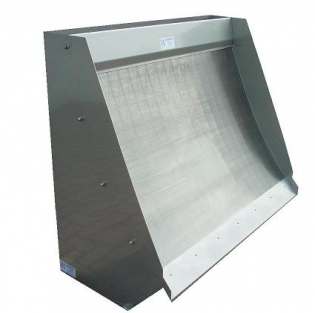

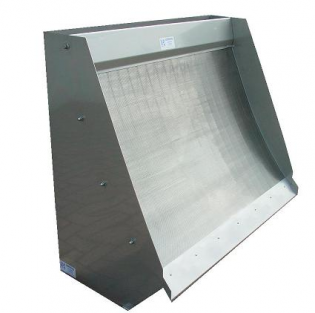

Model Siebostatic

Het standaard model zeefbocht is een zelfreinigend filtersysteem.

De vloeistofstroom over de zeefplaat is voldoende om ook de achtergebleven vuildeeltjes naar beneden te spoelen, waarna deze in de opvanggoot, afvalcontainer vallen.

Deze type zeefbochten hebben vaak een industriele of tuinbouw toepassing, waarbij de vuildeeltjes bestaan uit stof, zand en makkelijk te spoelen deeltjes.